and Power ports labeled." width="3324" height="1584" />

and Power ports labeled." width="3324" height="1584" />Many of the components of the FRC® Control System have indicator lights that can be used to quickly diagnose problems with your robot. This guide shows each of the hardware components and describes the meaning of the indicators. Photos and information from Innovation FIRST and Cross the Road Electronics.

A compact and printable Status Light Quick Reference is available.

Robot On and Disabled

Robot On and Enabled

Robot Off, roboRIO not powered or RSL not wired properly

Power

Brownout protection tripped, outputs disabled

Power fault, check user rails for short circuit

Status

On while the controller is booting, then should turn off

Software error, reimage roboRIO

Safe Mode, restart roboRIO, reimage if not resolved

Software crashed twice without rebooting, reboot roboRIO, reimage if not resolved

Constant flash or stays solid on

Radio

Not currently implemented

Comm

Communication with DS, but no user code running

Good communications with DS

Mode

Outputs disabled (robot in Disabled, brown-out, etc.)

RSL

and Power ports labeled." width="3324" height="1584" />

and Power ports labeled." width="3324" height="1584" />

On or Powering up

Bridge mode, Unlinked or non-FRC firmware

Bridge mode, Linked

No Fault - Robot Enabled

No Fault - Robot Disabled

If a PDP LED is showing more than one color, see the PDP LED special states table below. For more information on resolving PDP faults see the PDP User Manual.

Note that the No CAN Comm fault will occur if the PDP cannot communicate with the roboRIO via CAN Bus.

No Power/ Incorrect Polarity

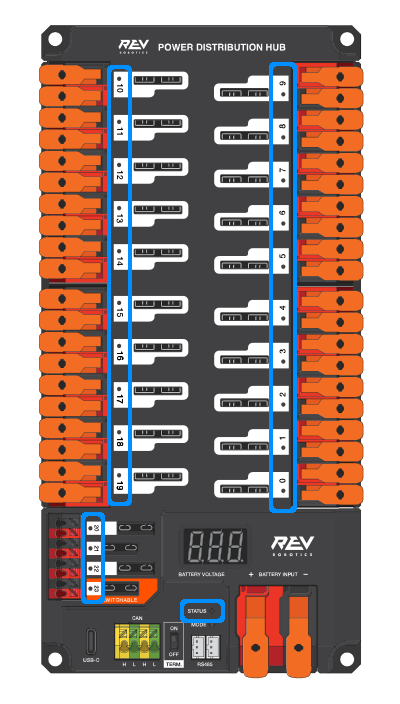

These led patterns only apply to firmware version 21.1.7 and later

Device on but no communication established

Main Communication with roboRIO established

Keep Alive Timeout

Secondary Heartbeat (Connected to REV Hardware Client)

Device Over Current

Channel has voltage and is operating as expected

Channel has NO voltage and there is an active fault. Check for tripped or missing circuit breaker / fuse

Sticky fault on the channel. Check for tripped circuit breaker / fuse.

The status LEDs on the VRM indicate the state of the two power supplies. If the supply is functioning properly the LED should be lit bright green. If the LED is not lit or is dim, the output may be shorted or drawing too much current.

No Fault Robot Enabled

No CAN Comm or Solenoid Fault (Blinks Solenoid Index)

If a PCM LED is showing more than one color, see the PCM LED special states table below. For more information on resolving PCM faults see the PCM User Manual.

Note that the No CAN Comm fault will not occur only if the device cannot communicate with any other device, if the PCM and PDP can communicate with each other, but not the roboRIO.

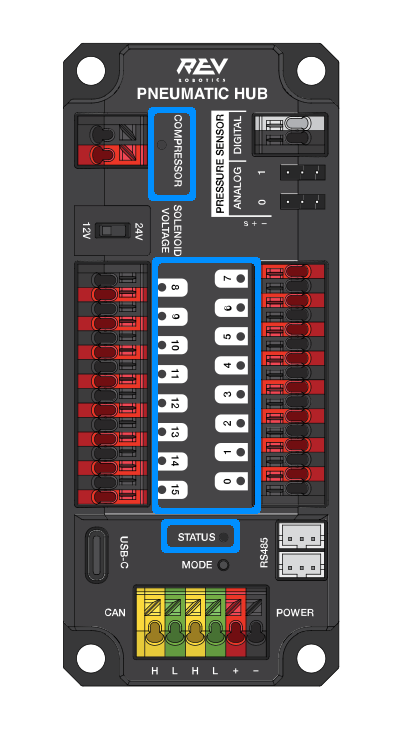

No Power/Incorrect Polarity

This is the Compressor LED. This LED is green when the compressor output is active (compressor is currently on) and off when the compressor output is not active.

These LEDs are lit red if the Solenoid channel is enabled and not lit if it is disabled.

These led patterns only apply to firmware version 21.1.7 and later

Device on but no communication established

Main Communication established

Keep Alive Timeout

Secondary Heartbeat (connected to REV HW Client)

Device Over Current

Talon SRX State

Forward throttle is applied. Blink rate is proportional to Duty Cycle.

Reverse throttle is applied. Blink rate is proportional to Duty Cycle.

No power is being applied to Talon SRX

CAN bus detected, robot disabled

CAN bus/PWM is not detected

LEDs Strobe towards (M-)

Forward Limit Switch or Forward Soft Limit

LEDs Strobe towards (M+)

Reverse Limit Switch or Reverse Soft Limit

LED1 Only (closest to M+/V+)

LEDs Strobe towards (M+)

Thermal Fault / Shutoff (Talon FX Only)

Status LEDs Blink Code

Talon SRX State

B/C CAL Button Color

Talon SRX State

Brake/Coast/Cal Button/LED - Red if the controller is in brake mode, off if the controller is in coast mode

Full forward output

Proportional to forward output voltage

Full reverse output

Proportional to forward output voltage

FRC robot disabled, PWM signal lost, or signal in deadband range (+/- 4% output)

Ready for calibration. Several green flashes indicates successful calibration, and red several times indicates unsuccessful calibration.

Full forward output

Proportional to forward output voltage

Full reverse output

Proportional to reverse output voltage

No CAN devices are connected

Disabled state, PWM signal lost, FRC robot disabled, or signal in deadband range (+/- 4% output)

No input power to Talon

Ready for calibration. Several green flashes indicates successful calibration, and red several times indicates unsuccessful calibration.

Full forward output

Full reverse output

Normal Operating Conditions

Neutral (speed set to 0)

Fast Flashing Green

Fast Flashing Red

Slow Flashing Yellow

Loss of servo or Network link

Fast Flashing Yellow

Slow Flashing Red

Voltage, Temperature, or Limit Switch fault condition

Slow Flashing Red and Yellow

Current fault condition

Calibration or CAN Conditions

Flashing Red and Green

Calibration mode active

Flashing Red and Yellow

Calibration mode failure

Flashing Green and Yellow

Calibration mode success

Slow Flashing Green

CAN ID assignment mode

Fast Flashing Yellow

Current CAN ID (count flashes to determine ID)

CAN ID invalid (that is, Set to 0) awaiting valid ID assignment

The DMC60C contains four RGB (Red, Green, and Blue) LEDs and one Brake/Coast CAL LED. The four RGB LEDs are located in the corners and are used to indicate status during normal operation, as well as when a fault occurs. The Brake/Coast CAL LED is located in the center of the triangle, which is located at the center of the housing, and is used to indicate the current Brake/Coast setting. When the center LED is off, the device is operating in coast mode. When the center LED is illuminated, the device is operating in brake mode. The Brake/Coast mode can be toggled by pressing down on the center of the triangle, and then releasing the button.

At power-on, the RGB LEDs illuminate Blue, continually getting brighter. This lasts for approximately five seconds. During this time, the motor controller will not respond to an input signal, nor will the output drivers be enabled. After the initial power-on has completed, the device begins normal operation and what gets displayed on the RGB LEDs is a function of the input signal being applied, as well as the current fault state. Assuming that no faults have occurred, the RGB LEDs function as follows:

PWM Signal Applied

No Input Signal or Invalid Input Pulse Width

Alternate between top (LED1 and LED2) and bottom (LED3 and LED4) LEDs being illuminated Red and Off.

Neutral Input Pulse Width

All 4 LEDs illuminated Orange.

Positive Input Pulse Width

LEDs blink Green in a clockwise circular pattern (LED1 → LED2 → LED3 → LED4 → LED1). The LED update rate is proportional to the duty cycle of the output and increases with increased duty cycle. At 100% duty cycle, all 4 LEDs are illuminated Green.

Negative Input Pulse Width

LEDs blink Red in a counter-clockwise circular pattern (LED1 → LED4 → LED3 → LED2 → LED1). The LED update rate is proportional to the duty cycle of the output and increases with increased duty cycle. At 100% duty cycle, all 4 LEDs are illuminated Red.

CAN Bus Control State

No Input Signal or CAN bus error detected

Alternate between top (LED1 and LED2) and bottom (LED3 and LED4) LEDs being illuminated Red and Off.

No CAN Control Frame received within the last 100ms or the last control frame specified modeNoDrive (Output Disabled)

Alternate between top (LED1 and LED2) and bottom (LED3 and LED4) LEDs being illuminated Orange and Off.

Valid CAN Control Frame received within the last 100ms. The specified control mode resulted in a Neutral Duty Cycle being applied to Motor Output

All 4 LEDs illuminated solid Orange.

Valid CAN Control Frame received within the last 100ms. The specified control mode resulted in a Positive Duty Cycle being Motor Output

LEDs blink Green in a clockwise circular pattern (LED1 → LED2 → LED3 → LED4 → LED1). The LED update rate is proportional to the duty cycle of the output and increases with increased duty cycle. At 100% duty cycle, all 4 LEDs are illuminated Green.

Valid CAN Control Frame received within the last 100ms. The specified control mode resulted in a Negative Duty Cycle being Motor Output

LEDs blink Red in a counter-clockwise circular pattern (LED1 → LED4 → LED3 → LED2 → LED1). The LED update rate is proportional to the duty cycle of the output and increases with increased duty cycle. At 100% duty cycle, all 4 LEDs are illuminated Red.

When a fault condition is detected, the output duty cycle is reduced to 0% and a fault is signaled. The output then remains disabled for 3 seconds. During this time the onboard LEDs (LED1-4) are used to indicate the fault condition. The fault condition is indicated by toggling between the top (LED1 and LED2) and bottom (LED3 and LED4) LEDs being illuminated Red and off. The color of the bottom LEDs depends on which faults are presently active. The table below describes how the color of the bottom LEDs maps to the presently active faults.